A solution for extending boiler life?

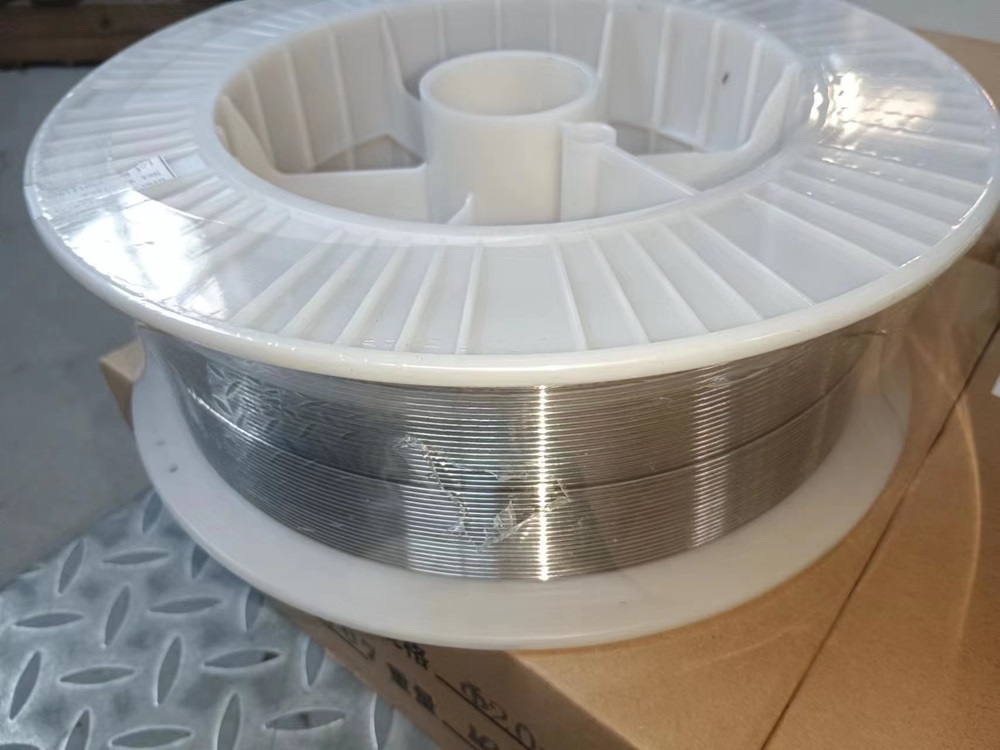

High-temperature and wear-resistant coating solutions: Use highly wear-resistant flux-cored welding wire / wear-resistant spray wire.

This is an advanced coating solution for boilers. With unmatched bond strength, it protects superheaters, waterwall tubes, and economizers from extreme heat, corrosion, and wear. No primer required.

The twin threats of coal-fired boilers: high temperature and wear

In the harsh environment of coal-fired boilers, component failure is unacceptable—it results in costly downtime. Critical areas like superheaters, waterwall tubes, and economizers are constantly under attack from both high-temperature corrosion and persistent fly ash erosion. Traditional coatings and surface treatments often prove ineffective, leading to frequent maintenance, reduced efficiency, and unplanned downtime.

But what if there was a more powerful protection? A solution that directly addresses these two threats while offering exceptional durability.

High-Wear Flux-Cored Welding Wire / Abrasion-Resistant Spray Wire: A Breakthrough in Protective Coating Technology.

Our high-wear-resistant flux-cored welding wire is designed for the extreme operating conditions within coal-fired boilers. This innovative material forms a protective coating that acts as a powerful barrier, providing dual protection where it's needed most.

The resulting coating offers the following characteristics:

Highly resistant to high-temperature corrosion: It withstands the corrosive chemical environment created by combustion byproducts, preventing material degradation.

Extremely resistant to erosion and wear: It resists the physical wear caused by the constant impact of fly ash and particulates, significantly reducing material loss.

Wear-Resistant Flux-Cored Welding Wire/Abrasion-Resistant Spray Wire: This advanced coating is ideal for protecting the most vulnerable components in the boiler system:

Superheaters and reheaters: Extend service life by protecting tubes from the hottest, most corrosive gas paths.

Waterwall tubes: Prevent wear and leaks in the lower furnace area (a common failure point).

Economizers: Protect these critical heat recovery components from wear and tear, maintaining efficiency.

Key Advantage: Superior Bond Strength, Eliminating a Critical Step

The most significant technical advantage of this flux-cored wire is its exceptionally high coating bond strength. This isn't just a minor improvement; it's a game-changer for application efficiency and reliability.

No Primer Required: Unlike many traditional coatings that require a bond coat or primer, this coating can be applied directly to the prepared substrate. This simplifies the process, reduces application time, and reduces the likelihood of intercoat failure.

Long-Lasting Adhesion: Superior adhesion ensures the coating remains securely in place even under intense thermal cycling and mechanical stress, providing long-term protection.

Ready to enhance your boiler's wear resistance?

Don't let high-temperature corrosion and wear dominate your maintenance schedule and budget. Our highly wear-resistant flux-cored wire/wear-resistant spray wire offers a rugged, reliable, and technologically advanced solution.

Contact us today to learn more about how to apply this coating to your boiler's water walls, superheaters, and economizer components.

Emial :sophiashen@canchunmetal.com

WhatsApp/wechat :+86 13722988404