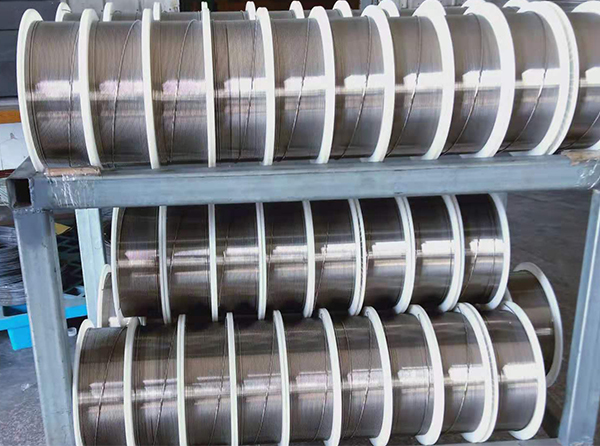

Inconel625 wire

Inconel625 is an alloy grade with a density of 8.4 g/cm3 and a melting point of 1290-1350°C. It has excellent resistance to inorganic acid corrosion and has excellent corrosion resistance to various corrosive media in oxidation and reduction environments.Mainly used for arc spray system and flame spray system ,it can equivalent to Metco8625,PMET889 ,TAFA71T.

Feature

Alloy 625 wire shows excellent corrosion resistance in many media. It has excellent resistance to pitting, crevice corrosion, intergranular corrosion and erosion in chloride media.

Specification

Diameter : 1.6mm

Package :15kgs/spool

Density : 8.4 g/cm3

Melting point :1290-1350°C

Inconel 625 chemical composition

% | Ni | Cr | Mo | Nb | Fe | Al | Ti | C | Mn | Si | Cu | P |

|

Min | Remain | 20 | 8 | 3.15 |

|

|

|

|

|

|

|

|

|

Max |

| 23 | 10 | 4.15 | 5 | 0.4 | 0.4 | 0.1 | 0.5 | 0.5 | 0.5 | 0.015 |

|

Application

The softened and annealed low-carbon alloy 625 is widely used in the chemical process industry. Its good corrosion resistance and high strength enable it to be used as a thinner structural part. Alloy 625 can be used in situations where it is exposed to seawater and subjected to high mechanical stress. Typical application areas:

1. Components of organic chemical processes containing chlorides, especially where acid chloride catalysts are used

2. Used in the manufacture of digesters and bleaching tanks in the pulp and paper industry

3. Absorption tower, reheater, flue gas inlet baffle, fan (wet), stirrer, baffle and flue in the flue gas desulfurization system

4. Used to manufacture equipment and components used in acid gas environments

5. Acetic acid and acetic anhydride reaction generator

6. Sulfuric acid condenser