Wear and Corrosion Resistant Materials: A Guide to Superior Performance

In industrial environments, equipment is constantly subjected to wear and corrosion. These factors lead to frequent downtime, high maintenance costs, and decreased productivity. Selecting appropriate materials is the most effective strategy to address these challenges and ensure the long-term stable operation of equipment.

So, what are the most common and effective Wear and Corrosion Resistant Materials?

The key categories of high-performance materials include:

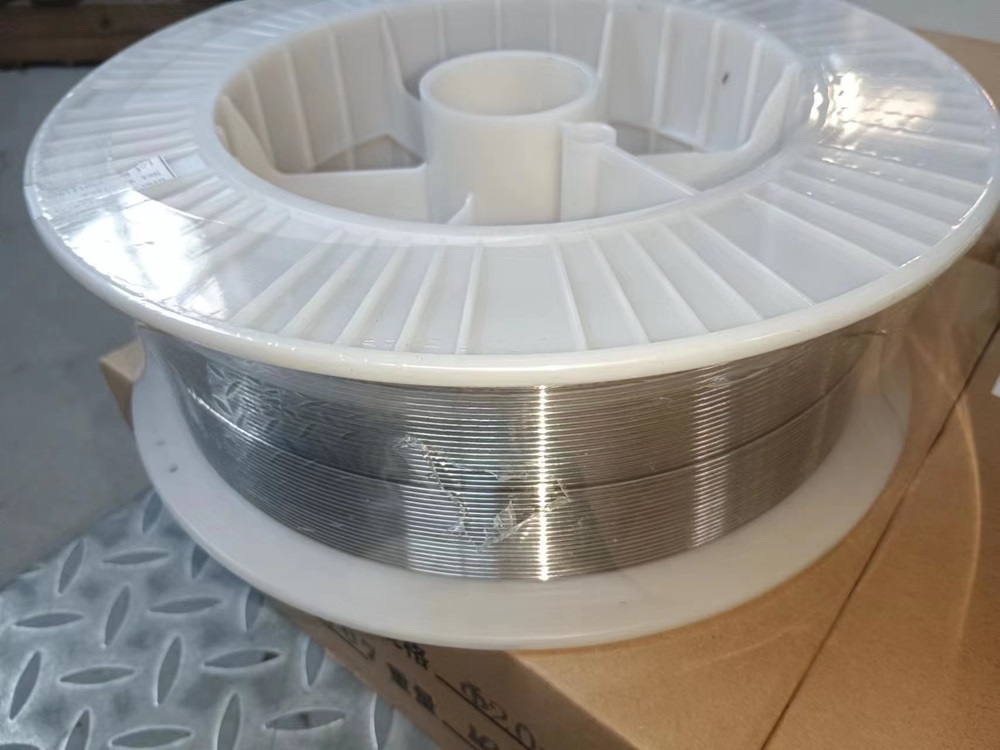

Stainless Steel / Chromium Alloy/ Titanium Alloy /Hardened Alloy .

Stainless Steel: A versatile choice known for its excellent corrosion resistance, especially grades with high Chromium and Nickel content. It forms a protective passive layer that prevents rust and oxidation in various environments.

Chromium Alloy: Chromium is a cornerstone of hardness and corrosion resistance. Alloys high in chromium, such as those used in hard-facing applications, provide exceptional resistance to abrasive wear and are fundamental in many stainless steels.

Titanium Alloy: Renowned for its outstanding corrosion resistance, particularly in chloride environments like seawater and chemical processing plants. Titanium alloys offer a superior strength-to-weight ratio and excellent resistance to pitting and crevice corrosion.

Hardened Alloy (Hard Metals/WC): This category often includes tungsten carbide (WC) and other cemented carbides. These materials are the ultimate choice for extreme abrasive wear applications, offering unmatched hardness and durability, though often paired with a tougher substrate for support.

Why These Materials Are the Ideal Solution

These advanced materials form a protective barrier, extending the lifespan of components such as pumps, valves, impellers, pipes, and cutting tools.

Reduced downtime: Reduces failures and replacements.

Low lifecycle cost: Minimizes maintenance and parts replacement costs.

High reliability: Maintains stable performance even under harsh conditions.

Whether you face mud abrasion, chemical corrosion, high-temperature oxidation, or mechanical wear, understanding these material categories is the first step to finding a solution.

Are you looking to protect your equipment with the right wear and corrosion resistant material?

Canchun provides you with high-quality materials and solutions to help your equipment run longer, stronger, and more efficiently. Contact us today: sophiashen@canchunmetal.com

WhatsApp: +86-137 2298 8404