Is surface wear, corrosion, or frequent part replacement driving up your operating costs?

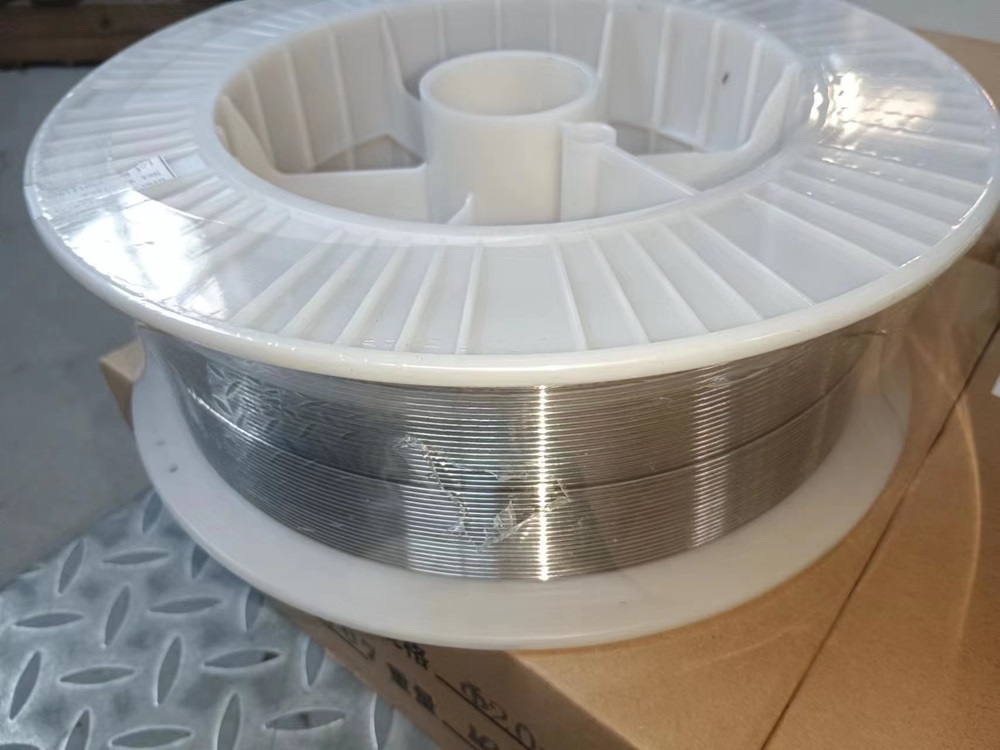

Thermal spray flux-cored wire offers breakthroughs in metal surface enhancement and equipment repair, helping industrial companies reduce downtime and extend asset life.

Why choose thermal spray flux-cored wire?

Our advanced wire combines the versatility of thermal spray with the efficiency of flux-cored wire to create superior solutions for:

* High-wear resistance – rebuilding crushers, shafts, rollers, and dies.

* Corrosion protection – protecting components in chemical, marine, and offshore environments.

* Precision repair – restoring dimensional accuracy without expensive replacement.

* Cost reduction – saving 50-70% compared to new parts; minimizing production downtime.

Transform your maintenance strategy

For mining, power generation, manufacturing, and heavy industry:

Use hardened, customized coatings to extend equipment life up to 3 times.

Eco-efficiency – reducing waste and energy consumption compared to traditional manufacturing. On-site application – repair on-site, eliminating disassembly delays.

How it works

Arc spray or HVOF processes melt flux-cored wire.

A dense, bonded coating (carbide, alloy, ceramic) is applied to the worn surface.

Components regain their original strength or even higher within hours.

Ready to reduce costs and increase uptime?

Canchun Metal Products Trading Co., Ltd. offers customized flux-cored wire solutions to meet your toughest surface

challenges.

Contact us now:

sophiashen@canchunmetal.com

WhatsApp: +86-13722988404