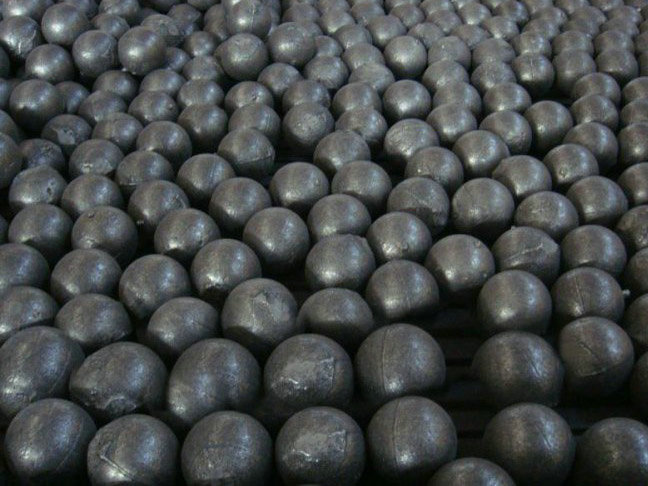

Heat treatment in grinding ball production is a process of which grinding

ball being heat and kept in a certain temperature under certain circumstances

and cooled. The grinding ball heat treatment process is quenching.

Quenching has been widely used in modern machinery manufacturing industry.

The important mechanical parts are almost being quenched, especially in

automobiles, aircraft and rockets.

The grinding ball quenching is heating grinding ball to a suitable

temperature and keeping thermostatic after a period of time, then immersing ball

into quenching medium for rapid cooling, so grinding ball microstructure is

transferred with hot and cold alternating. Sometimes, grinding ball also need to

be tempered after quenching. Grinding Ball tempering process is worked with

thermal conditions of different temperatures. The tempered grinding balls can

greatly improve the metal strength, toughness and labor intensity, thereby

improving its wear resistance.

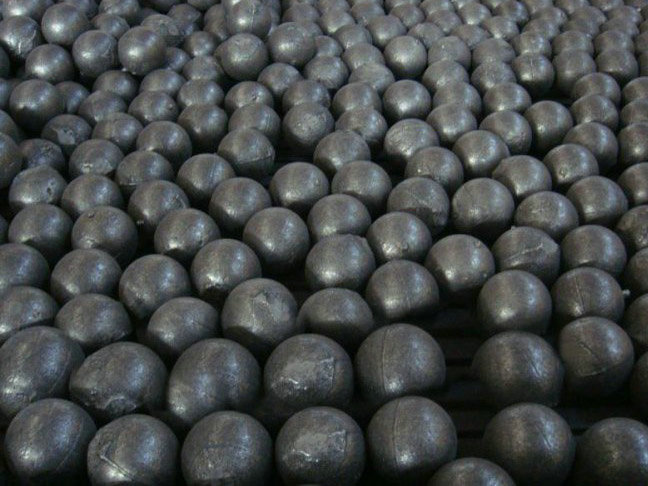

Grinding ball quenching purpose is transferring supercooled austenite to

martensite and making change inside the metal structure of microstructure, and

then with different tempering temperature, to achieve substantial strength,

hardness and fatigue resistance, finally meet the requirements of crushing load

and wear resistance.